Valmet MCA - Microwave

The most versatile and precise total consistency measurement

The Valmet Microwave Consistency Measurement (Valmet MCA) delivers reliable total consistency measurement for a wide range of process controls independent of flow rate or fiber type.

Stay on your consistency target

Advanced microwave technology makes the Valmet MCA the most accurate and reliable total consistency measurement regardless of flow rate, fiber brightness or color. The Valmet MCA uses fast raw measurement and high sample volumes to deliver exceptional measurement results covering a wide consistency range of 0% to 16%.

Because it measures all solid particles in the process, the Valmet MCA enables better control for more efficient production, improved quality and economic savings with fewer process upsets. This is particularly true in applications where fiber quality and characteristics can vary significantly.

Reliable accuracy everywhere

Unaffected by fiber mixes, grade changes or filler variation, the microwave transmitter is ideal for demanding processes in pulp and paper, textile, water treatment, and many other industries. Using an advanced Direct Sweep Detection method together with specially designed antennas and digital electronics, the Valmet MCA delivers reliable measurements for the best process control performance.

From chemical dosing to recipe and grade mix management and basis weight control, you can rely on the Valmet MCA. Processes with high furnish variations, for example, are easier to control with Valmet MCA thanks to its ability to measure accurately without specific calibration. Refining processes benefit immensely as well. The high degree of consistency control opens up opportunities for energy savings while supporting effective quality management.

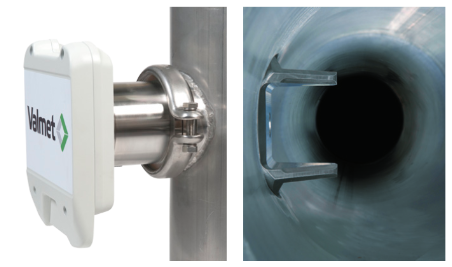

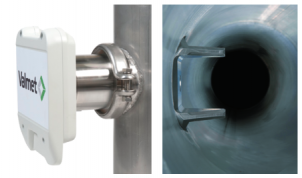

The optional Twin Blade sensor with higher conductivity limits and chemical compensation allows Valmet MCA to be used for applications that were difficult for microwave sensors. Designed for large-diameter pipes, the Twin Blade offers easier, more flexible installation and better performance compared to many other microwave sensor solutions.

Simple measurement management

Commissioning and operation are a snap with the Valmet Bridge, a touchscreen control platform designed for Valmet process sensors and analyzers. An intuitive graphical interface underscores the ease of single-point calibration. The Valmet Bridge also has its own memory so that operators can get insights from trend visualizations.

Additional integrated measurements, such as temperature, pressure, and vibration detection, support operating diagnostics to verify performance. With comprehensive diagnostics and Industrial Internet capabilities, the Valmet Bridge provides intuitive access to Valmet MCA operation and remote services from Valmet.

Measuring range: 0 – 16 %Cs (if > 16 %Cs or outside Pulp and Paper applications, consult with Valmet)

Repeatability: ±0.01 %Cs

Sensitivity: 0.001 %Cs

Damping: 1 to 99 s

Ambient temperature: -20...+70 °C (-4...+158 °F), protect from direct heat radiation

Valmet MCA Sensors:

Enclosure class: IP-65 (NEMA 4)

Wetted materials

- MCA FT sensors: AISI 316, AISI 316L, Ceramic

- gasket: EPDM, Simrit 483

- MCA F sensor: AISI 316L, Ceramic

- (options for MCA F sensor) AISI 316L replaced with Titanium

- GR2 or Hastelloy C276

- gasket EPDM, Simrit 483

- Process coupling materials: AISI 316L

- (options for MCA F sensor): Titanium GR2 or Hastelloy C276

- Mounting clamps and screws: AISI 316

Accurate total consistency - Get reliable consistency measurements for any kind of fiber process

Stable production control - Quickly react to changes without needing to recalibrate

Low lifetime costs - Simple to use and completely maintenance-free