Valmet Nove - Cs% Sampler

Reliable consistency samplers for pulp and paper

Used widely by pulp and paper mills around the world, the Valmet Consistency and High Consistency Samplers (Valmet Nove and Nove H) deliver dependable samples for laboratory analysis.

Market-leading reliability

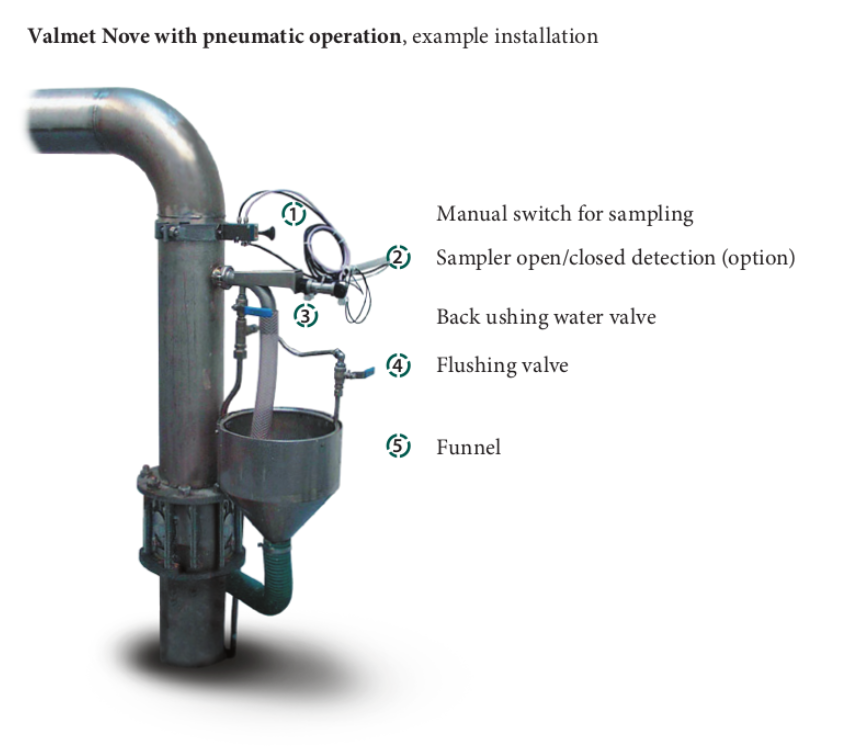

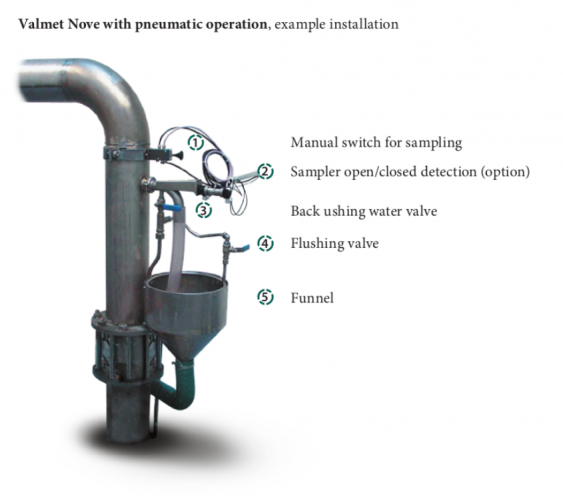

A testament to its reliability and performance, the Valmet Consistency Sampler (Valmet Nove) is the most used pulp sampler type on the market. Engineered for screened pulp with consistency from 0 to 8%, the Valmet Nove comes in two models for manual or pneumatic sampling operation.

For consistencies up to 18%, we offer the Valmet High Consistency Sampler (Valmet Nove H). The Valmet Nove H can be used in screened as well as unscreened pulp applications.

Suitable for all pulp grades, Valmet Nove and Nove H can be easily installed in a wide variety of processes with different process couplings and materials available. The Valmet sampler construction is proven to reduce standard laboratory test variation by 50% compared to typical ball-valve samplers.

Easy and accurate sampling every time

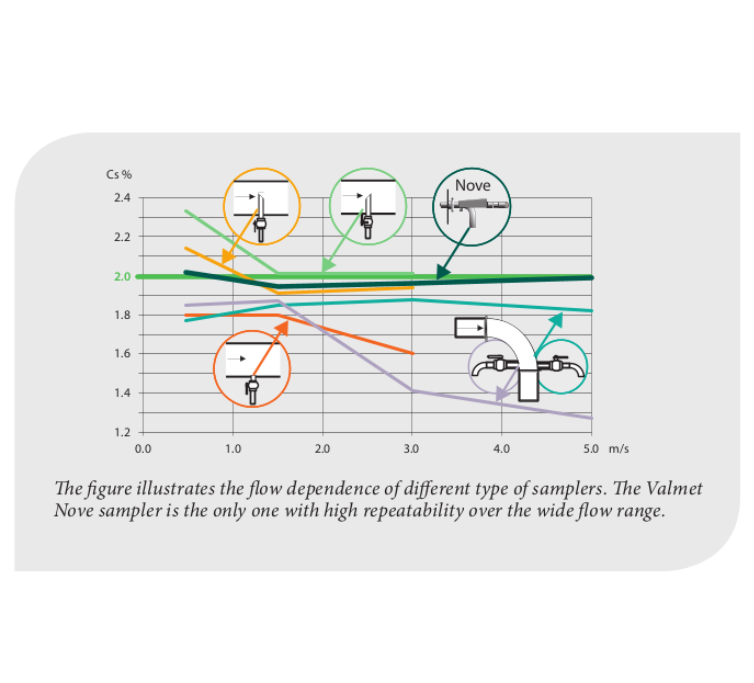

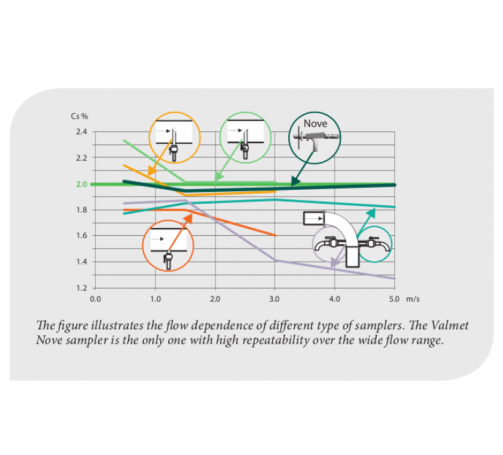

The construction of the Valmet Nove and Nove H and a built-in flushing feature ensure representative sampling year after year. The samplers are insensitive to flow variations, and they are designed to reduce variations caused by operator sampling practices.

The flow of the sample is easily adjustable, as is the stroke of the piston, providing exactly the required flow rate for each application. The piston is engineered to ensure blockage-free operation with an automatic and sturdy closing mechanism preventing debris from causing spills or other damage.

Samplers can be equipped with an open/close detector for automatic syncing. The sampler detects when a sample is taken and stores the measurement result for later analysis or calibration for superior consistency management and process control. This also ensures safe use in harsh processes environments that have abrasive chemicals, high temperature and/or high pressure.

As an additional safety measure for Valmet Nove H, we offer the optional Muki H collection component. When Nove H is opened and closed, the sample flows into the Muki H collector where it can be collected at a safe distance from the process pipe.

Applicability

- Consistency range: 0–8 % Cs

Materials

- Parts in constant contact with process medium: see type specification chart

- Other parts: AISI 316L

- Pneumatic cylinder: aluminum alloy

- Piston shaft: hard-chromed steel

Supply air pressure

- When pressure is lost, a return spring in pneumatic

actuator shuts the valve.

- P min.: 1/3 x process pressure

- P max.: 10 bar (145 psi)

Process conditions

- When process pressure is > 10 bar, the strength of the

connection between process coupling and process pipe

must be calculated separately in accordance with the

pressure endurance of the pipework; connection must

be reinforced if necessary.

- Temperature: max. 120°C (248°F)

- Pressure minimum: see Graph 1 (manual)

- Pressure maximum: 25 bar (350 psi)

For fiberglass-reinforced plastic coupling:

- Pressure max. .............. 16 bar (232 psi)

High repeatability - Built-in resilience to variations in flow and operator sampling

Safe sampling - Engineered for safe sampling in harsh environments

Automated operation - Support for automatic syncing of sampling