Valmet OC - Optical

Inline optical measurement for ash and total consistency

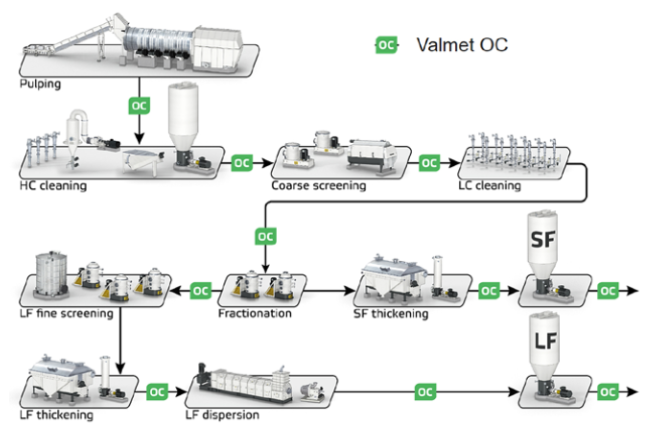

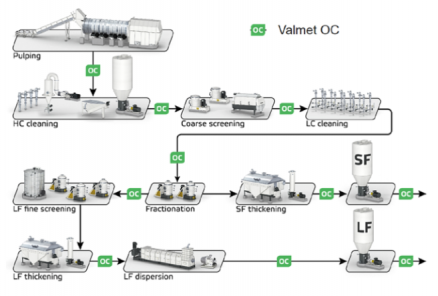

The Valmet Optical Consistency Measurement (Valmet OC) is suitable for many consistency applications thanks to a range of sensor probe options.

Accurate total consistency and ash measurement

The Valmet Optical Consistency Measurement employs multiple optical fiber channels, a single light source and optimized probe designs to deliver reliable consistency measurements. There are no electronics or other sensitive components within the probe, making it resistant to high temperatures, pressure and vibrations.

Known for its accuracy, reliability and ease of use, the Valmet OC family of solutions are fully optimized for specific applications. All solutions measure total consistency (0 – 12%), with the Valmet OC2R providing an additional, independent ash measurement from 0 to 10%.

The Valmet OC2R offers the possibility to measure ash in recycled pulp, as well as general stock preparation applications in paper, tissue and board, opening new possibilities for greater control of stock preparation processes.

Optimal performance for every application

The original Valmet OC employs the latest technology for applications in mechanical pulping, including TMP, GW and CTMP, cyclone cleaner, latency removal, screening, and low consistency refining. Alongside the original Valmet OC, we offer application-specific solutions.

The Valmet OCR probe is engineered for robustness to withstand the harsh physical environment of recycle fiber processes. It also features a special multi-point calibration for ash to handle variations that normally disrupt inline optical consistency measurements. A typical example is stock preparation where various raw components are being mixed.

No longer limited to washed pulp, the Valmet OCS features a chemical-resistant sapphire window that enables accurate inline consistency measurement with chemical pulp. Applications cover the early stages of the blow line all the way to pulp storage or drying machine.

We also offer the Valmet OCE, engineered specifically for eucalyptus pulp which has unique optical properties compared to other pulps. A typical application is the control of refiner feed consistency, where accurate inline consistency improves refiner freeness and reduces energy consumption.

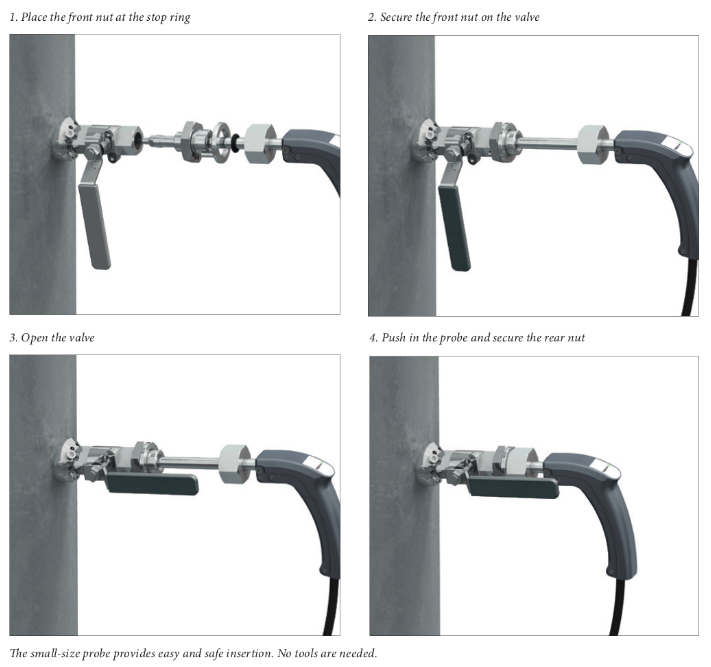

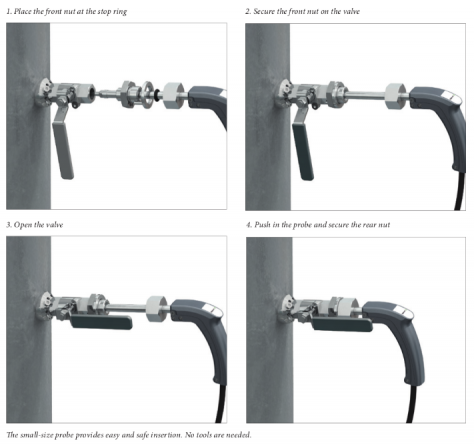

Easiest optical measurement available

Extremely easy to install, the Valmet OC is a low-cost, high-value investment. Minimal welding and no sensitive components on the process pipe make Valmet OC robust, requiring no regular maintenance.

A profiled coupling design ensures the probe position is correct. The probe is self-cleaning and retractable without special tools, so process shutdown is not required when removing the probe. It’s completely safe to remove, even at high process pressure.

Calibration is quick with just one laboratory sample. Specific curves for varying pulp types are stored in the transmitter for easy selection. For demanding applications, multi-point calibration is available with Valmet OCR and OC2R.

All Valmet OC transmitters offer the full advantages of HART, Profibus PA technologies, as well as online condition monitoring with Fieldcare or AMS systems.

SENSOR PART

Measurement:

- Span min.: 0.5 % Cs

- Damping: adjustable, 1–60 sec

Materials:

- Enclosure: Polycarbonate

- Wetted parts: AISI 316L

- O-ring material: VITON

Process conditions:

- Temperature: 0 to +120 °C (+32 to +248 °F)

- Vibration: max. 2G (20 m/s2), 10–2000 Hz

Environment:

- Ambient temperature: –20 to +60 °C (–4 to +140 °F)

- Temp. during storage: –50 to +80 °C (–50 to +176 °F)

EMC test standards:

- Radiated interference: IEC 61000-6-2

- Interference immunity: IEC 61000-6-4

Weight:

- Sensor + Optical TCU.................................... 3.9 kg (8.6 lbs)

VALMET OC OPTICAL TCU

Connections:

- TCU to Optical Unit: length 0.7 m (2.3 ft)

- Optical cable: length 5 / 10 m (16.5 ft / 33 ft)

- Operating power: 90–260 VAC, 47–63 Hz, 1 A

- Power consumption: max. 25 W

Connections to mill system:

- Analog outputs: 2 current outputs, 4–20 mA

- HART®: 12–35 VDC

- Binary inputs: 2 inputs, galvanically isolated 12–28 VDC / 10 mA

PROFIBUS PA Slave (option)

IEC 61158-2

- Profibus power supply: from the bus

- Bus voltage: 9–32 VDC, reverse polarity protection

- Max. basic current: 14.2 mA

Connections to PC (configuration & diagnostics)

- DTM: HART®

- PC-connection (service):RS-232

Environment:

- Ambient temperature: max. 50 °C (max. 122 °F)

- Enclosure class: IP65 (NEMA 4)

- Vibration (TCU + Optical Unit): max. 1 G (10 m/s2), 10–2000 Hz

Weight:

TCU: 2 kg (4.4 lbs)

TCU + Optical Unit: 3 kg (6.6 lbs)

Options: when TCU and Optical Unit separated

- K15278, 10 m Sensor Cable option

- K13507, 10 m Extension Cable

Safe and simple - Quick installation and a self-cleaning, retractable probe with minimal maintenance

Measure consistency with confidence - Reliably accurate total and ash consistency in a wide consistency range

Special purpose sensors - Sensor probes engineered to deliver best results for specific applications