Valmet Rotary - Rotating Meas.

Reliable fiber consistency measurement

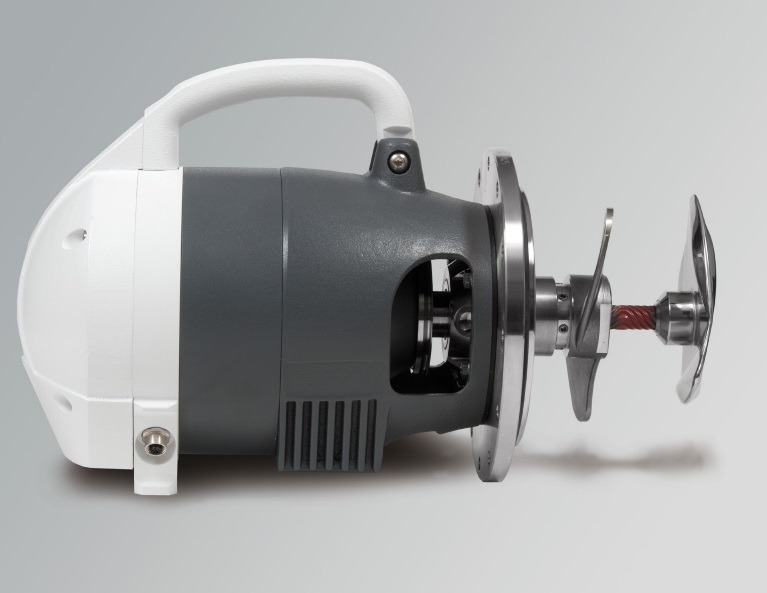

Setting a new standard in rotary consistency measurements, the Valmet Rotating Consistency Measurement (Valmet Rotary) delivers extremely high sensitivity while cutting maintenance effort.

Stay on spec with fast measurement responses

The rotating sensor solution has been a preferred choice for numerous applications in pulp and paper mills for decades. As the industry evolves to meet new sustainability and economic demands, processes must be able to run at maximum production capacity.

The Valmet Rotary technology helps you meet your fiber consistency requirements immediately. Pulp mills with high temperatures, for example, benefit from the long life of the robust sensor structure and component selection. The Valmet Rotary can be installed to pipe sections where other shear force sensors cannot work.

The strong motor ensures trouble-free startup and reliable mixing in unfavorable process conditions. A complete range of sensing elements across the entire measurement range secures near universal application of Valmet Rotary.

Valmet’s solution responds rapidly to consistency variations, helping you stay in control of your optimum operating window. After process disruptions, you can be back on-spec faster than ever.

Durability and precision for challenging processes

The strength of the Valmet Rotary construction has been proven in process environments as well as in many endurance tests carried out by independent research institutes.

The Valmet Rotary performance remains excellent even in challenging environments such as high temperature or pressure and abrasive chemicals. This is in large part thanks to Valmet's Direct Torque, the industry's most reliable shear force consistency measurement.

Gone are the days of slow force balance stabilization. The Valmet Rotary is extremely quick. The patented Direct Torque combined with our Metal-to-Metal Precision sealing technology delivers unbeatable results: fast, reliable, and sensitive.

Specifications and process conditions:

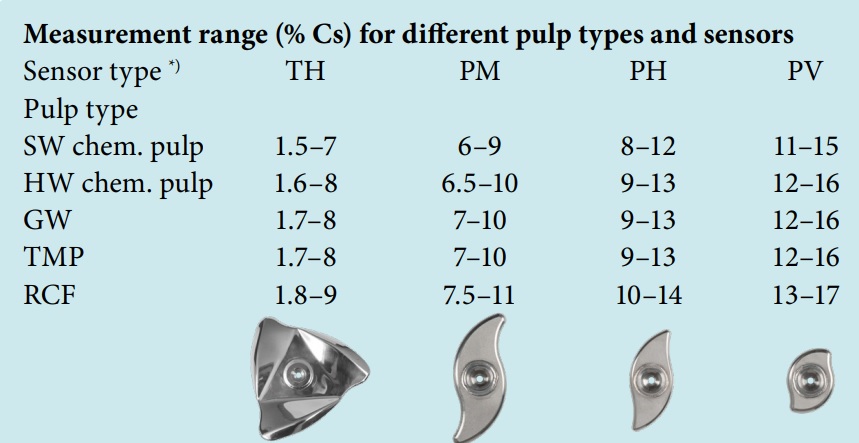

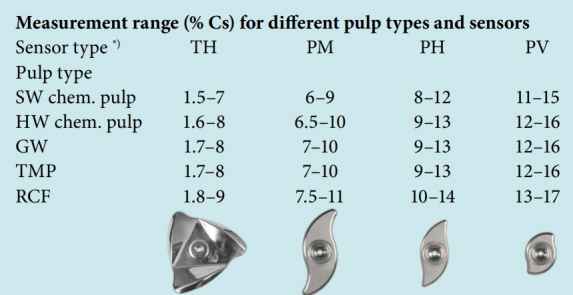

- Measuring range: 1.5…18% Cs (see table for more specific data)

- Repeatability: ± 0.01% Cs

- Sensitivity: 0.004% Cs

- Damping: 1…60 s

- Ambient temperature: –20…+70 °C (–4…158 °F) BD model

- Ambient temperature: –20…+50 °C (–4…122 °F) MD model

Valmet Rotating Consistency Measurement sensors:

- Sensors: See table for more specific data

- Enclosure class: IP65 (NEMA4X)

- Housing: Aluminum alloy

- Wetted materials: AISI 316L, 254 SMO®

Operating unit, TCU:

- Enclosure class: IP65 (NEMA4X)

- Operating voltage: 90…260 VAC/0.1A

- Outputs: current output Consistency 4–20 mA + HART® 18…35 VDC

- Inputs: 2 inputs, isolated 12-48 VDC

- Communication: Profibus PA / PC connection: RS-232 (Support for FieldCare and DNAfield Assessor)

Motor – MD model (1-phase):

- Operating voltage: 230 VAC

- Power rating: 0,37 kW

- Enclosure class: IP65 (NEMA 4X)

Motor – BD model (3-phase):

- Operating voltage: 200–690 VAC

- Power rating: 0.25 kW

- Enclosure class: IP55 (option: IP56)

- Stable, accurate measurement - Measure fiber consistency with extremely high sensitivity

- Fast response - New, patented technology ensures rapid measurement response

- Simplified maintenance - Easy on-site maintenance for low overall lifetime cost