Valmet SP - Blade

Cost-effective consistency measurement for pulp and paper

Valmet Blade Consistency Measurement (Valmet SP) is the most used consistency measurement worldwide. With decades of experience and proven performance built-in, the Valmet SP offers accuracy, reliability and the longest lifetime.

Measure consistency in any pulp and paper process

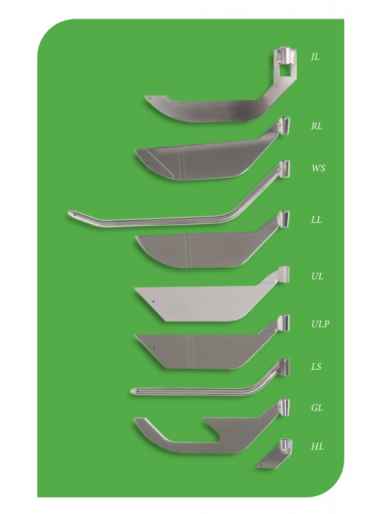

The Valmet SP is truly a universal consistency measurement solution. Our portfolio of options, including a variety of sensing elements, allows you to configure the sensor for practically any pipe size and layout.

With a consistency measurement range from 0.7 to 16%, the Valmet SP is the most important part of an automatic consistency control loop. The Valmet SP is suitable for chemical kraft pulp, mechanical pulp, recycled pulp, DIP, OCC and so forth. It can be used in the blow line, screening, washing, bleaching, refining, stock preparation, mixing and machine chest. You get a stable and accurate measurement even when process conditions have variations.

For optimal performance, the Valmet SP should be installed where the process has a laminar flow. Turbulence reducers are available to further stabilize measurement in challenging locations.

The freely available Valmet Measurement Advisor can be used to determine the best installation position and Valmet SP model. The tool also provides tailored installation instructions for specific process conditions.

Measurement

- Consistency range: 0.7–16 % Cs

- Span:

- minimum: 0.8 % Cs

- maximum: 30 N – zero elevation

- Zero elevation: max. 30 N – Span

- Damping: adjustable, 1–60 sec

Performance

- Tested in reference conditions in accordance with IEC60770.

- Linearity of force meas: ± 0.5 % of span

- Hysteresis: 0.025 N

- Repeatability: 0.01 N

- Static pressure effect: 0.02 N per 1 bar

- Process temperature effect: 1% of reading per 10°C

- Vibration effect (2 G per 10–2000 Hz): less than ±0.03 N

Process conditions

- Process temperature: 0…+120 °C

- Process pressure: max. 25 bar

Wide applicability - Suitable for all process flows in pulp and paper operations

Quick startup - Simple installation and startup with preset calibration curves

Low maintenance - No moving parts and no preventative maintenance required